I've recently implemented an inverse kinematics (IK) solution to enhance the precision and control of robotic leg movements. Our primary experiment involved programming the leg to execute a simple rectangular movement pattern, with a focus on maintaining accuracy and consistency. Here, I will share some intriguing geometrical observations and challenges we encountered.

Intended Path and Test Setup

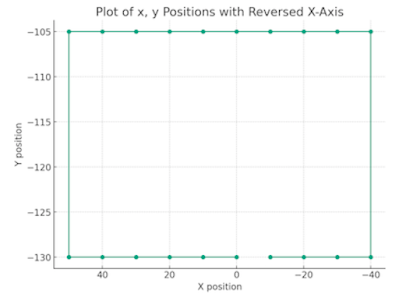

For this test, the robot leg will start in the (0,-130) position. Moving clockwise, It steps backward (in my case more positive, note the inverted x axis) to the (50, -130) position. Next up by 25mm to the top. At this time I use a different z position, but it is hard to see. the motion continues around in a rectangle ending at the start.

Planned path for simple gait test. starting at the center bottom

Video Analysis

In the bolow short video, the robot steps through the gait path. The leg is mounted above the table and horizontal to the table, not in a typical robot position. I have traced each step of the path, with a small dot at the end of the foot.

As seen in the video, the motion lacks the expected precision, influenced by several factors:

- Fixture Stability: The fixture holding the leg is unstable, contributing to erratic movements.

- Manual Marking Inaccuracy: Yellow dots indicating key positions were marked by eye, leading to imprecision.

- Servo Calibration: The calibration of the servo points was approximative. At a setting meant to be 90°, the actual angle could range between 85-95°.

Geometrical Challenges: The Skew Issue

One of the more fascinating issues we observed is the skew to the left when the leg is raised vertically. This skew is likely influenced by the constraints of the 'solution space'—the range within which the actuator operates. As a result, there is a slight warping effect in the grid area over which the leg can move.

|

| Mojo5 Inverse Kinematics - geometric skew |

Implications of the Skew

- Motor-Driven Distortions: The two servomotors, designed to drive the leg in specific rotational angles, do not guarantee a perfectly perpendicular alignment of the movement path. This introduces a mathematical distortion in the intended trajectory.

- Impact on Gait Creation: While this skew does not necessarily hinder the robot's ability to perform meaningful gaits, it highlights an essential aspect of robotic movement—geometric imperfections inherent in mechanical and software solutions.

Further Research on the Mapped or Solution Space

- Reachability: Determined by the length of the robot's arms and the range of motion of its joints. The maximum and minimum extents of each joint define the outer and inner boundaries of this space.

- Compliance: In the context of SCARA robots, the vertical compliance allows for certain movements in the vertical plane within the workspace. This selective compliance helps in absorbing forces during tasks like assembly, where vertical give is beneficial.

- Kinematic Constraints: Defined by the robot's mechanical design and the kinematic equations governing its movements. These constraints delineate the paths and patterns the robot can execute.

- Control Resolution: The precision with which the robot's controllers can position its joints also defines the resolution within the mapped space, influencing how finely the robot can maneuver within its reach.