It is a Compliant Quadruped Walking Robot Dog.

Mojo - the name of my pet Dog

Compliant - the springs in the leg provide 'mechanical compliancy', storing and adding energy to the walking gait

Quadruped - Four (4) legs

Walking - It moves with a gait or walking motion - no wheels here

Robot - Mechatronics at its best, a microcontroller 'brain' and servos to convert the digital to the physical

Dog - or other representative small quadruped - Jack Russell Terrier to be exact! ;)

Compliant - the springs in the leg provide 'mechanical compliancy', storing and adding energy to the walking gait

Quadruped - Four (4) legs

Walking - It moves with a gait or walking motion - no wheels here

Robot - Mechatronics at its best, a microcontroller 'brain' and servos to convert the digital to the physical

Dog - or other representative small quadruped - Jack Russell Terrier to be exact! ;)

There are now a few iterations of this Idea:

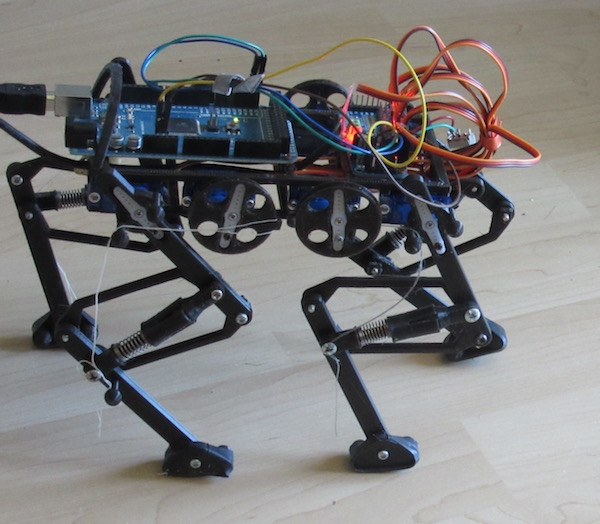

Original Mojo 2018

|

| Mojo (1) - The first iteration (so cute and small :) ) |

Mojo2 - created with much stronger, hobby servo motors. It was the first Mojo design capable of walking.

|

| Mojo2 - Oct 30th 2018 - Larger servos |

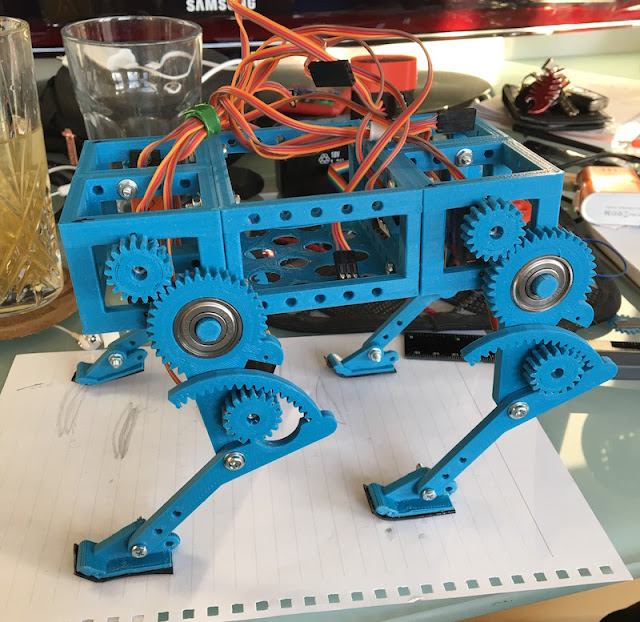

Mojo3 - used a geared design on the legs. I tired to make it very light in order to use very small hobby servos. The servos were not able to support the robot and move forward. It was still to heavy and required a lot of torque. I like the blue color!

|

| Mojo3 - Geared Leg Design |

Mojo4 was really more of a Franken-prototype. It uses the concept of a 5bar linkage for the walking. ultimately it failed due to the large current pull on the battery.

Mojo5 is under development. Spring 2024

Mojo Videos:

Here is the first walking videos:

For the complete history and Introduction to Mojo read through the topic posts for the Label "Mojo". Mojo was inspired by the robotic work done at the ETH Zurich Robotics Lab, researching biomimicry of animal gaits in robotics.

Mojo is completely designed, 3D printed, and built as part of my Totally Not Evil Robot Army. Design work was created in OpenSCAD and printed on a Creality CR10 3D printer. Mojo is controlled by own built software running on a Arduino mini pro microcontroller. It uses an PCA9685 servo 16 channel servo driver board to control 8 servos. Batteries are provided for servo power and microcontroller operation. Special Serial Elastic Actuators (SEA) were designed and built using 3D printed parts and parts from recycled printers. The knee cam and hip servo control is directly inspired by ETH Zurich design - but uniquely designed and built independently by myself.

Please contact me if you are interested in additional information.

No comments:

Post a Comment